Mobile Warehouse Inventory System

Mobile-first FIFO inventory management dramatically reducing spoilage and streamlining warehouse operations with real-time Android tracking.

The Challenge

Warehouse operations previously relied on clipboards and manual data entry to track inventory movements, leading to inaccurate physical counts, poor stock rotation (FIFO) compliance, and delays in locating specific pallets.

Staff struggled to quickly determine the oldest received date for items, increasing the risk of expiration and product spoilage.

The Digital Asset

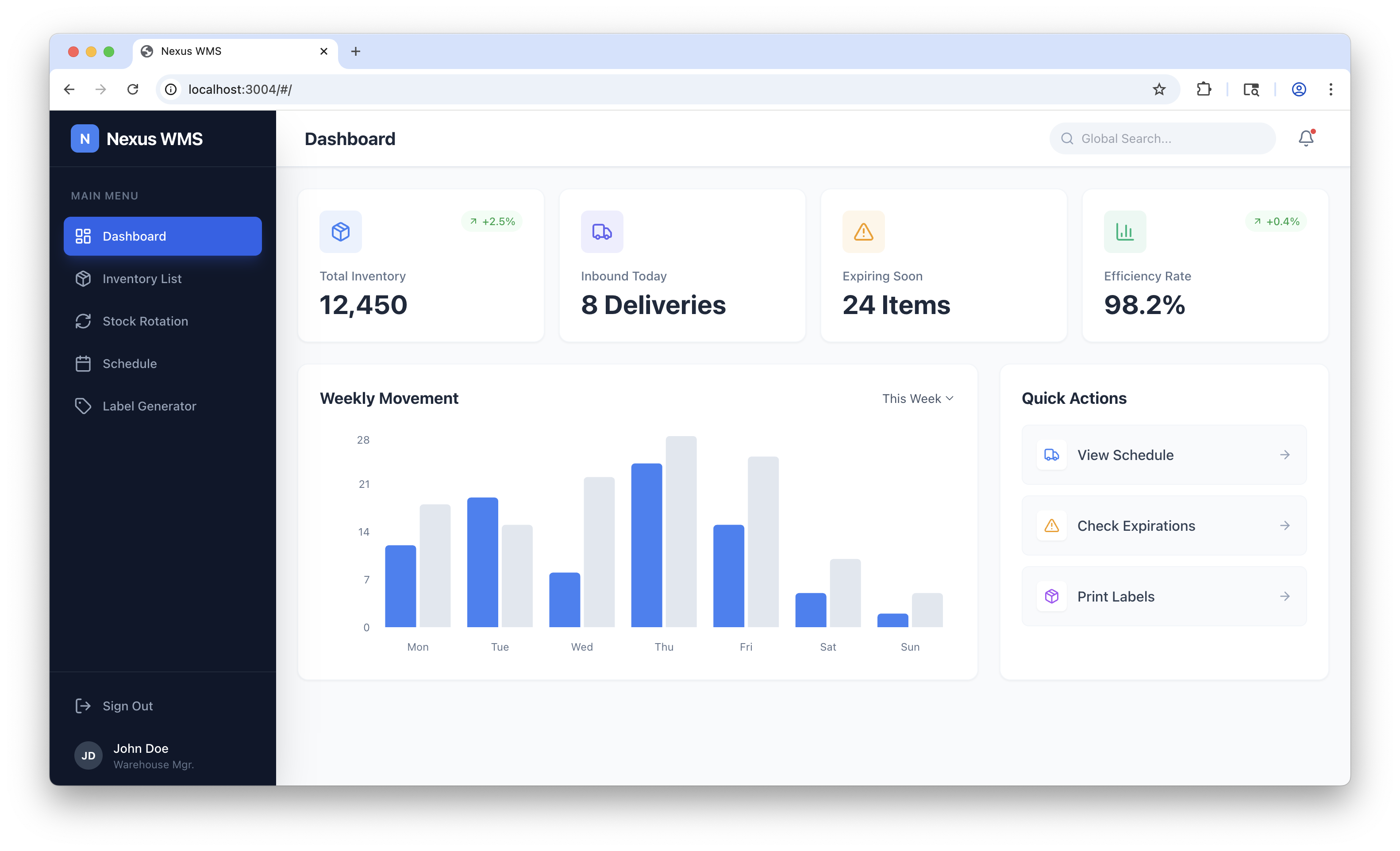

We designed a mobile-first Stock Rotation application on Android and a comprehensive inventory tracking system that connects physical warehouse locations to digital records. Staff can instantly Receive, Move, or Adjust inventory by scanning item codes.

Key Capabilities

- Mobile Stock Rotation interface with one-tap access to Receive, Move, Adjust

- Digital item search and adjustment via numerical keypad

- Master inventory tracking by Received Date, Inv. Tag #, Exp. Date, Location

- Delivery schedule dashboard for incoming shipments

- Integrated label printing with barcode data

- Real-time synchronization with master inventory system (Heartland Edison)

Business Impact

Drastically Reduced Spoilage

FIFO compliance displays items by Received Date and Expiration Date, ensuring oldest stock is pulled first, drastically minimizing waste.

Real-Time Accuracy

Mobile Adjust and Move functions record physical stock changes instantly, providing highly accurate Quantity on Hand (QOH) data.

Accelerated Receiving

Edison Labels feature allows staff to quickly print standardized SKU labels with tracking data, streamlining the receiving process.

Optimized Efficiency

Ruggedized Android device eliminates manual write-downs and desktop data entry, making warehouse staff significantly more productive.

The Bottom Line

This mobile system put inventory management directly in warehouse staff hands. No more clipboards—receive, move, and adjust stock in real-time with proper FIFO rotation.

The result: dramatically reduced spoilage, accurate stock counts, and warehouse staff focused on operations—not paperwork.